Outokumpu Long Products expresses ambition to be leader in high performance products

by David Fleschen

Outokumpu Long Products ambition is to be the leader in high performance stainless steel long

products, providing solutions for the most demanding customer applications. The product offering

consists of bars, wire rod, wire and semi-finished cast products in a broad range of sizes and grades.

Long Products is known for high quality, delivery reliability and technical expertise and delivery of highly

effective solutions for customers.

Long Products Business Area is a fully integrated producer situated in four locations, three of them

being in Europe. Outokumpu has its melt shop, wire rod mill and bar production facility in Sheffield, UK.

In Sweden: Fagersta Stainless produces wire and wire rod. Degerfors Long Products produces rolled

billets and bars. The fourth location is in the US with a bar production facility Outokumpu Stainless Bar

in Richburg South Carolina.

The extended bar offering is now covering all sizes for round bars from 6 to 200 mm. With our

developed improved machinable grade Prodec, there is a potential saving of 50 % on component cost

and 100% longer tool lifetime. In addition, we offer peeled k11 and polished and ground h9 bars up to

80 mm in major grades. The offering in special shaped bars in hexagon and square sizes ranges from 8

to 24 mm, with our partner Böllinghaus and their combined offering customers can benefit of very wide

size range in the special shaped bars.

Wire rod and Wire offering

The rolling mills in Sweden and UK produce wire rod from 5mm to 27.5 mm. Drawn wire if produced

from 1.5mm to 15mm. Our customers can find material for applications from springs, cold heading

products, welding wire to spokes wire. The material is also used for further re-rolling and bar production.

Outokumpu made an investment in 2019 to modernize Fagersta Stainless rolling mill in Sweden. This

enabled the mill to expand into new high value-added special products, improve the working

environment and to reduce carbon emissions of the mill. New equipment’s retain heat in the billets and

enable higher rolling temperature, lower energy consumption and overall efficiency.

The ASR mill in the UK produces round, hexagon, and square wire rod as well as rebar. Bar and wire

producers, as well as welding companies, rely on Sheffield’s wire rod mill for uniquely specialized

products in a wide range of grades

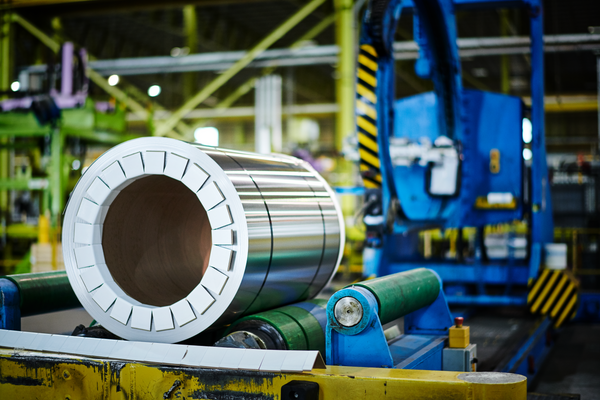

Semi-finished products offering

Outokumpu’s Semi-finished stainless steel long products are produced in concast slabs, concast billets

& blooms as well as rolled and forged billets. We have an extremely wide selection of grades, shapes

and sizes, including our 300 mm slab. Semi-finished products are available in austenitics, duplex,

superduplex, high alloyed austenitics, martensitics and PH-grades.

Source and Photo: Outokumpu