Rethinking supply - recycled raw materials for industrial resilience

by Dagmar Dieterle-Witte

Steel is the backbone of modern industrial societies, playing a key role in everything from infrastructure and automotive production to the energy transition. However, the industry is currently facing fundamental structural challenges. On the one hand, there is rising decarbonization pressure, and on the other hand, there are growing uncertainties along global supply chains. Alongside decarbonization, ensuring a stable supply is becoming a critical strategic issue.

"We need to rethink industrial production — not only from a climate perspective, but also with regard to the availability of raw materials," explains Denis Reuter, COO of the TSR Group. "Recycled raw materials are far more than just a promise of sustainability. They are a future-proof building block for resilient and sustainable value chains. They combine ecological requirements with economic reliability, offering industry a solution that can be implemented today."

"We need to rethink industrial production — not only from a climate perspective, but also with regard to the availability of raw materials," explains Denis Reuter, COO of the TSR Group. "Recycled raw materials are far more than just a promise of sustainability. They are a future-proof building block for resilient and sustainable value chains. They combine ecological requirements with economic reliability, offering industry a solution that can be implemented today."

TSR40 is suitable for industry, recyclable, and available.

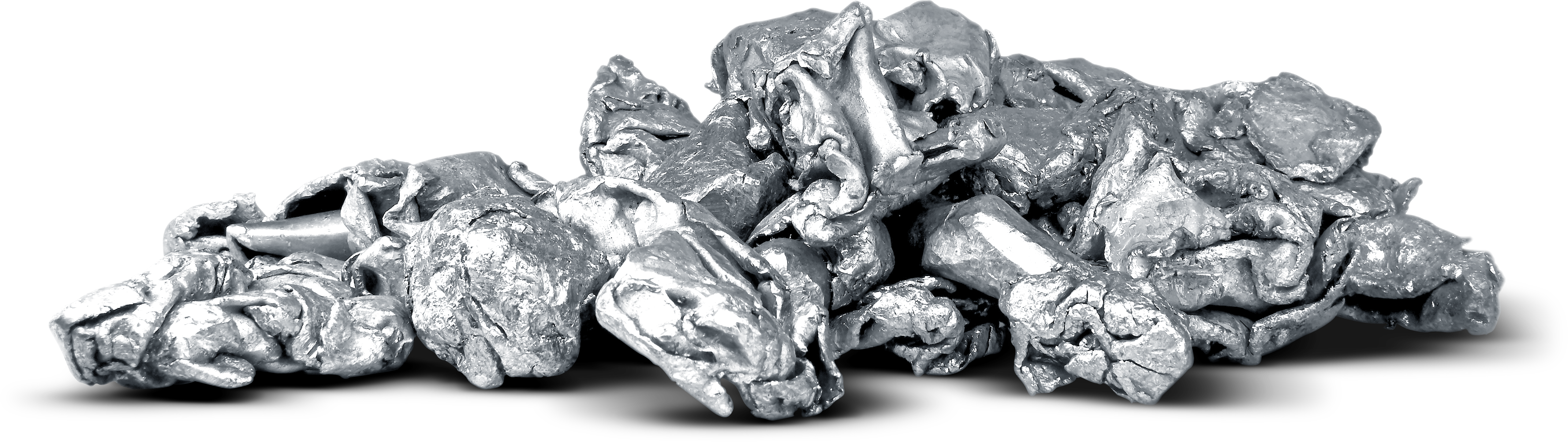

As one of Europe's leading metal recycling companies, the TSR Group has developed a recycling product designed to meet the needs of modern steel production. This product is made entirely from post-consumer materials. End-of-life vehicles, mixed scrap, and household appliances are processed using special measuring, detection, and separation techniques in a multi-stage process. The result is TSR40, a recycling product that can be used in converters, blast furnaces, and electric arc furnaces for steel production.

"With TSR40, we are setting new standards in raw material quality," says the TSR managing director. Interfering elements are identified and removed during production, and accompanying elements, such as copper, nickel, and chromium, are analyzed and determined with precision. "This allows us to offer the steel industry a raw material that meets the requirements of the highest quality steel applications, with which the proportion of recycled material can be significantly increased. We have already successfully demonstrated this in several projects with automotive manufacturers."

Scalable infrastructure for resilient cycles

Scalable infrastructure for resilient cycles

The increasing demand for quality-assured recycled raw materials and the need to use existing resources efficiently make the expansion of processing capacities a central component of TSR's raw materials strategy. The company is therefore making targeted investments in a scalable infrastructure to process post-consumer material streams to a high standard and make them reliably available to the steel industry. The first plant was commissioned in Duisburg in 2023, followed by another in Amsterdam in 2024. Additional plants are currently being planned and built.

In addition to availability, TSR40 offers the industry ecological benefits: Compared to production using primary raw materials, the use of the recycled product not only saves CO₂ emissions, but also reduces energy requirements and conserves natural resources. Denis Reuter says: "TSR is thus providing a recycled raw material that stands for a resilient and sustainable supply of raw materials. The company is making a decisive contribution to closed cycles at an industrial level, which is already contributing to the decarbonization requirements of the steel industry."

In addition to availability, TSR40 offers the industry ecological benefits: Compared to production using primary raw materials, the use of the recycled product not only saves CO₂ emissions, but also reduces energy requirements and conserves natural resources. Denis Reuter says: "TSR is thus providing a recycled raw material that stands for a resilient and sustainable supply of raw materials. The company is making a decisive contribution to closed cycles at an industrial level, which is already contributing to the decarbonization requirements of the steel industry."

Photos:

TSR40 processing plant on the raw material island in Duisburg

TSR40 - a high-quality recycled product for a resilient and sustainable supply of raw materials for the steel industry.

TSR, Denis Reuter