Invisible but essential: how Air Liquide underpins the semiconductor boom

by David Fleschen

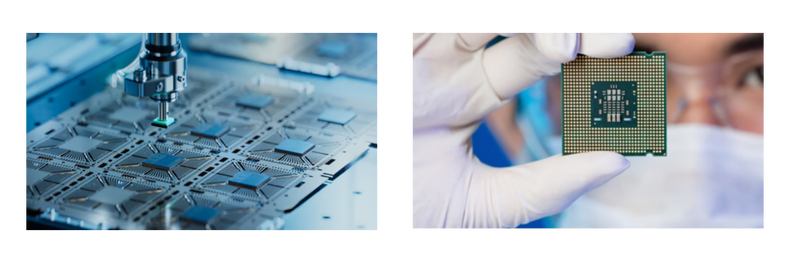

As global demand for computing power accelerates, semiconductors have become one of the most strategic industrial products worldwide. Behind the race for smaller, faster and more powerful chips lies a largely invisible but critical supply chain – and at its core are ultra-pure gases and advanced materials supplied by Air Liquide.

Speaking in January, Armelle Levieux, Vice President of Innovation, Hydrogen and Electronics at Air Liquide, said the group is focused on “accompany[ing] our customers in semiconductor manufacturing to tackle the challenges of this fast-growing industry,” pointing to the central role played by gases and materials that rarely attract public attention.

Semiconductors themselves are materials whose electrical conductivity can be precisely controlled – a property that allows billions of transistors to be packed onto a single chip. A modern smartphone processor can contain between 5 and 20 billion transistors, while leading-edge AI chips already exceed 80 billion. Producing such devices requires one of the most complex industrial manufacturing processes ever developed.

That complexity is now driving a global investment wave in new semiconductor fabs, as artificial intelligence and digitalization fuel unprecedented demand for performance. Yet even the most advanced chips depend on basic physical inputs that must meet extreme purity standards.

“What is the connection between Air Liquide and the smart devices we use in everyday life?” asked Guillaume Cottet, Vice President of Air Liquide Electronics. “These devices all rely on increasingly powerful, miniaturized chips. And behind those tiny essential components, you will find Air Liquide molecules.”

Air Liquide supplies ultra-pure industrial gases such as nitrogen, argon and oxygen, as well as rare gases like krypton and xenon, to all of the world’s top ten semiconductor manufacturers. These gases are used throughout the fabrication process, which can take several months and involves hundreds of highly sensitive steps. Even microscopic contamination can destroy a chip, making cleanroom conditions and gas purity critical.

The volumes involved are enormous. A single semiconductor fab can consume tens of thousands of cubic meters of high-purity gases every day. To guarantee reliability, Air Liquide increasingly produces gases close to customer sites or directly on-site, reducing logistical risk and strengthening supply security.

Rare gases, despite their name, are not scarce in nature but occur in the atmosphere at extremely low concentrations. Extracting them requires cryogenic distillation, in which air is cooled to ultra-low temperatures and separated by boiling point – a process that demands both scale and technical expertise.

Beyond gases, advanced materials are playing a growing role in next-generation chip production. These highly engineered molecules are designed for specific functions in leading-edge processes, enabling better connectivity, higher computing power and lower energy consumption.

“Making a semiconductor chip is a feat of precision,” Air Liquide notes. “Circuits are etched at the nanometer scale, over a million times smaller than a human hair. Our goal: zero defects.”

To support this rapidly expanding market, Air Liquide is investing heavily in new production capacity near major semiconductor hubs. Recent projects include investments of more than €250 million in Europe, additional capacity for the US market, and a €130 million project in Singapore to supply a major chip manufacturer.

Mihaela Satrapeli, Vice President Markets & Customers at Air Liquide Electronics, said the group is “deeply committed to delivering essential molecules and advanced materials to chip manufacturers,” adding that Air Liquide is “proud to help power the innovations that will shape the next digital revolution.”

For steelmakers and metals suppliers watching the semiconductor boom from the outside, the message is clear: even the most advanced digital technologies ultimately rest on industrial processes, materials and infrastructure that are every bit as demanding as those in traditional heavy industry – and increasingly interconnected with it.

Source and Photo: Air Liquide