New collaboration to implement grid-friendly power supply system

by David Fleschen

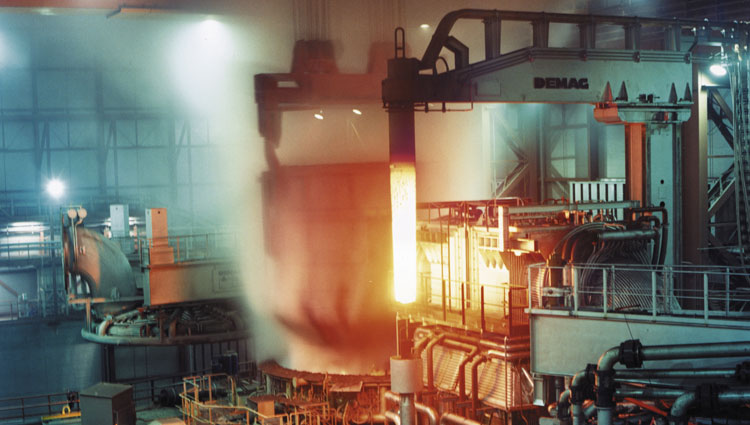

BGH Edelstahl in Siegen, Germany, has signed an agreement with Primetals Technologies to test the Active Power Feeder solution at its 50-ton electric arc furnace (EAF). Active Power Feeder is projected to be ready for operation under industrial production conditions at EAF plants by 2025.

Active Power Feeder is a key technology for green electric steelmaking. It utilizes a patented and proven medium voltage modular multilevel converter (MMC) technology in a ground-breaking power control system developed by experts at Primetals Technologies.

Thanks to Active Power Feeder, the power supply system will operate maintaining high power quality – at a level that meets the requirements of power utility companies. Additionally, the power supply system ensures low electrical losses and high furnace efficiency.

Another benefit of Active Power Feeder is its highly flexible installation options. Whether a steel producer is looking at modernizing an existing EAF or plans to implement a new meltshop, the solution will support the corresponding implementation procedures. Moreover, Active Power Feeder can compensate also for the extra strain put on the power supply system if an additional ladle furnace is introduced. All these features are realized without the need for an extra static VAR compensator (SVC) or a static synchronous compensator (STATCOM).

The collaboration between BGH Edelstahl and Primetals Technologies will demonstrate the environmental, technical, and commercial benefits of the technology under industrial production conditions for scrap melting with EAFs. BGH Edelstahl’s furnace will be powered by an Active Power Feeder featuring a 3-phase indirect modular multilevel converter (MMC).

BGH is a specialty steel producer of stainless steels and special alloys of the highest quality. The wide product range also encompasses small batch sizes for special requests and requirements from BGH’s end customers, such as precisely timed deliveries and highest quality standards. BGH is committed to reducing their Scope 1 and Scope 2 CO2 emissions by 42 percent by 2030 compared to the 2021 baseline. Also, the German steel producer aims to reduce Scope 3 emissions by 25 percent during the same timeframe and compared with the same baseline.

Source and Photo: Primetals