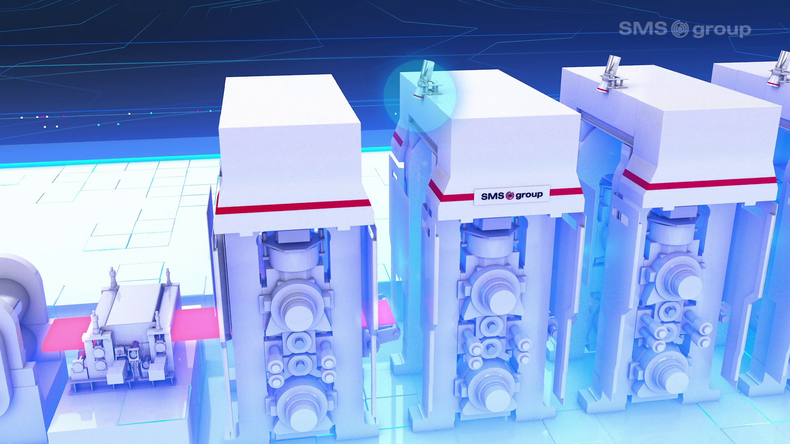

Salzgitter Flachstahl boosts rolling stability with X-Pact® Centerline Control

by David Fleschen

Salzgitter Flachstahl GmbH has reached a new milestone in the modernization of its seven-stand hot strip mill with the successful integration of SMS group’s X-Pact® Centerline Control system. The upgrade, completed in March 2025, enhances rolling stability, improves strip alignment, and reduces manual interventions during production.

The X-Pact® Centerline Control is an advanced strip guiding automation system that uses industrial cameras and real-time image processing to detect and correct lateral deviations during rolling. The system ensures precise strip alignment and mitigates common issues such as double-rolled edges, ripped tail-ends, and cobbles. The result is improved uniformity in thickness and winding, reduced internal stresses, and a consistent surface finish.

Installed as part of a wider technology package ordered from SMS group in 2024, the system integrates seamlessly into Salzgitter’s existing automation environment. Image processing data is transmitted to the Level 1 control system, enabling the hydraulic gap control unit to adjust the seven stands dynamically. Operators benefit from a user-friendly HMI interface and automated control loops that minimize unscheduled downtimes.

According to Thomas Rothe, head of Salzgitter’s hot strip rolling mill, “The system has proven to be highly effective and has performed beyond our initial expectations.”

The project continues a long-standing collaboration between Salzgitter Flachstahl and SMS group, whose partnership dates back to 1963. The cooperation reflects a shared commitment to innovation, digitalization, and process optimization in steel production.

Source and Photo: SMS Group