SMS to replace the largest converter in North America at AMD

by Hans Diederichs

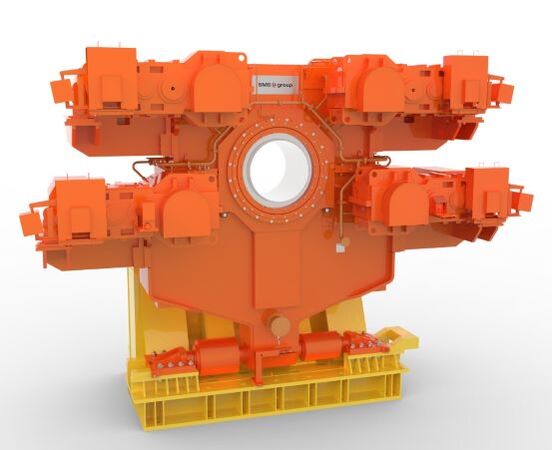

ArcelorMittal Dofasco (AMD), Canada, has awarded SMS group Inc. the contract to supply a replacement 320-ton KOBM converter and gear drive for its steel making plant in Hamilton, ON, Canada. The converter at ArcelorMittal Dofasco is the largest basic oxygen converter in North America.

The project goals are to replace the existing equipment, which is approaching its end of life, with new equipment incorporating the latest technological developments. One featured technology is the unique SMS group electro-hydraulic torque compensator, which is a system that actively reduces the resultant forces generated by highly dynamic bottom blown converters. This will reduce the dynamic loading on the entire system, with resulting increases in availability and life.

The patented SMS group torque compensator has been designed to operate with both the existing and new gear reducers. The new torque restraint system will be installed and fully commissioned on the reducer for the existing converter, during a vessel reline outage in May 2020. It will then be incorporated into the new reducer during the complete converter replacement, scheduled for the second quarter of 2021.

The overall project scope of supply includes the converter vessel, trunnion ring, the proven lamella-type vessel suspension system, trunnion bearings, gear reducer, hydraulic torque compensator system, the X-Pact® electrical and automation systems for the compensator, and supervision of erection and commissioning.

The high-performance gearbox, manufactured at the SMS workshop in Germany, will be designed for high reliability and a long service life under tough operating conditions. The gearbox will be equipped with a main gear having an optimized case hardening depth. With a diameter of 3,500 millimeters (137.8 inches), the main gear will be one of the largest applied in a converter drive system in the world. The advanced gear design results in a superior contact pattern in all loading conditions.

SMS group will ship the complete vessel and trunnion ring assembly in one piece, considerably reducing the overall assembly effort on site.

At the Hamilton plant, AMD annually produces 4.5 million net tons of high- quality steel used in a wide range of industries, including the automotive, construction, manufacturing, packaging, distribution and tubular segments.

Source and photo: SMS group