Tenova and GE Vernova to supply record-size EAF for Nippon Steel

by David Fleschen

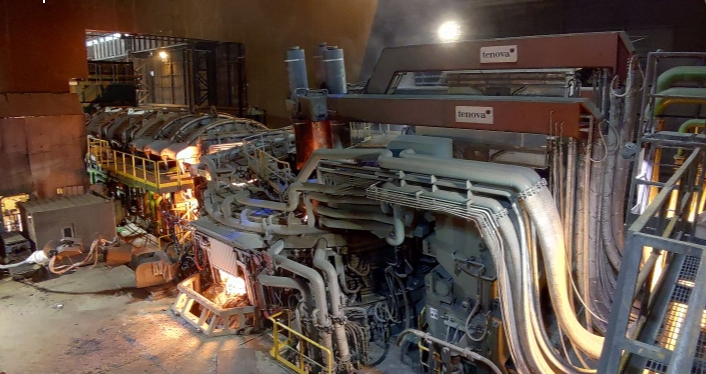

Tenova, in collaboration with GE Vernova, has been selected by Nippon Steel to supply a new Consteel® electric arc furnace (EAF) for the Yawata area of the company’s Kyushu Works, supporting Japan’s Green Transformation agenda and Nippon Steel’s 2050 carbon neutrality targets.

With a heat size of 340 tonnes, the new furnace is set to become the world’s most powerful EAF. The high installed power will enable the use of high shares of virgin iron units, a key requirement for the production of high-quality steel grades. GE Vernova will provide its Direct Feed power system to supply the high-stability power needed for an installation of this scale.

Paolo Argenta, Tenova Executive Vice President, Upstream Business Unit, said: “We are thrilled to collaborate once again with one of the world’s leading steelmakers, Nippon Steel. This record-setting EAF is not only an engineering achievement, but it also embodies a shared commitment with GE Vernova to sustainability that defines the future of our industry.”

The project marks a strategic step in Nippon Steel’s transition from blast furnace-based production toward EAF steelmaking as part of its long-term decarbonisation pathway.

Ed Torres, Business Leader, Power Conversion & Storage at GE Vernova, commented: “We are proud to collaborate with Tenova and Nippon Steel on a project that represents the future of sustainable steel production. Our Direct Feed solution shows how advanced power technologies can support energy-intensive industries in operating more efficiently and reliably while accelerating their long-term decarbonization goals.”

Source and Photo: Tenova